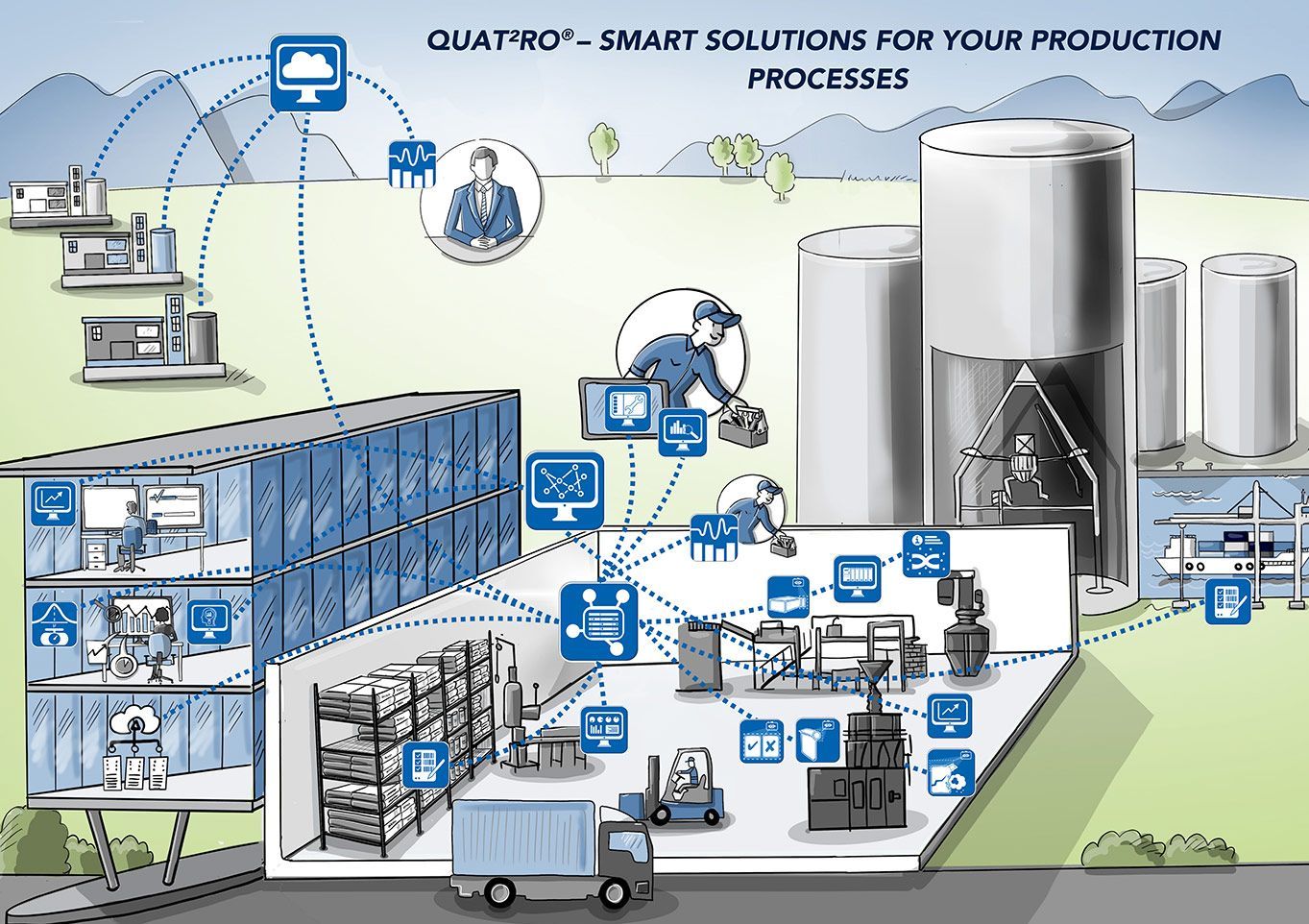

QUAT²RO® System Intelligence

Cloud-based platform for the two applications: QUAT²RO® Monitoring and QUAT²RO® Analytics.

QUAT²RO® Monitoring

Make your systems transparent and communicative. Automatically, effortlessly, and securely receive real-time data from your systems—anytime, anywhere.

QUAT²RO® Monitoring

Make your systems transparent and communicative. Automatically, effortlessly, and securely receive real-time data from your systems—anytime, anywhere.

QUAT²RO® Analytics

Leverage your system data over the long term with the support of OEM experts, transforming it into optimized operating conditions, targeted service interventions, and precise spare parts requirements.

QUAT²RO® Remote

Fast remote service for any situation: with direct support from OEM service experts, immediately and live, using cameras and smart glasses.

QUAT²RO® Production

Connect all machines and components in your production facility and seamlessly integrate them with your ERP system, enabling reciprocal, automated data exchange throughout the entire production process—the heart of your production.

QUAT²RO® Basis

Receive process automation precisely tailored to your requirements—the foundation for automation at the machine level.

QUAT²RO® Batch

The system ensures precise and reproducible execution of mixing processes, maintains consistent quality through automatic weight control and tolerance monitoring, and provides valuable support for your quality management with comprehensive traceability of all processes and raw materials.

QUAT²RO® Process Visualization

Operate, observe, and monitor your production processes, and gain the best possible overview with clear process visualizations on various devices.

QUAT²RO® Data

Your software module for capturing, displaying, and statistically analyzing weighing data.

QUAT²RO® Logistics

The logistics automation system optimizes your intralogistics by digitizing and automating the entire shipping, goods receipt, and logistics system—from packaged or loose goods to loading, raw material intake, and shipping, all the way to inventory management.

QUAT²RO® Logistics

The logistics automation system optimizes your intralogistics by digitizing and automating the entire shipping, goods receipt, and logistics system—from packaged or loose goods to loading, raw material intake, and shipping, all the way to inventory management.

QUAT²RO® Connect

The central, locally-operated platform for capturing all production events—serving as the foundation for applications such as QUAT²RO® Insights and QUAT²RO® Dashboards.

QUAT²RO® Insights

Obtain comprehensive analyses of downtime and production metrics. This application enables in-depth investigation of machine data to identify patterns and causes of production disruptions. With detailed displays and analytical tools, you can derive targeted actions to improve operational processes.

QUAT²RO® Dashboards

Maximize the value of your data with customizable real-time insights into your machine events and production metrics. This application provides a central overview of all relevant data from your production lines, enabling you to make immediate decisions and effectively monitor your machine performance. With flexible dashboard design, you can visualize your data according to your specific needs.

QUAT²RO® Dashboards

Maximize the value of your data with customizable real-time insights into your machine events and production metrics. This application provides a central overview of all relevant data from your production lines, enabling you to make immediate decisions and effectively monitor your machine performance. With flexible dashboard design, you can visualize your data according to your specific needs.

QUAT²RO® Valve Check

Precise monitoring of valve bag openings minimizes the risk of incorrect application in your packaging processes, supported by advanced camera technology and artificial intelligence (AI).

QUAT²RO® MatEx Check

Material leakages and bag bursts are detected in real-time, reducing product loss and optimizing your filling efficiency. The system is supported by advanced camera technology and artificial intelligence (AI).

QUAT²RO® Seal Check

The system performs real-time quality control of bag seals by utilizing advanced camera technology and artificial intelligence (AI) to ensure the integrity and tightness of your packaging.

QUAT²RO® Bag Check

The system utilizes advanced camera technology and artificial intelligence (AI) to ensure that the correct bag is selected for the specific material being filled, thereby ensuring precise matching to meet the highest quality standards.

AI-Supported Valve Bag Opening Detection with QUAT²RO® Valve Check

Our new AI-Innovation

Discover QUAT²RO® Valve Check – the groundbreaking innovation for your industrial packaging processes. Equipped with artificial intelligence (AI), this system minimizes the risk of incorrect valve bag applications by precisely monitoring the opening of the bags using the latest camera technology. Experience maximum efficiency, reduced product losses, and significant cost savings through precise control and seamless integration into your packaging lines.

Digital Product Solutions for Efficient Mixing Systems of Tomorrow

For the Perfect Process: QUAT²RO® Batch & QUAT²RO® Process Visualization

We are at Home in Your Field of Business

Our digital product solutions play a central role in maximizing the efficiency of your production processes in numerous industries.

Our customer-specific automation solutions and management systems consider the different characteristics and various requirements within the cement, building materials, chemical, mining, and food industries. We work with you to develop your very own customized solution!

Digital Services for Your Packaging Technology

Our Product Group QUAT²RO® System Intelligence

Benefit from the intelligence of your systems. QUAT²RO® System Intelligence for communicative processes.

- Transparent process monitoring

- Rapid support via remote service

- Optimized processes thanks to the analysis and interpretation of your system data

Find out more:

- HAVER & BOECKER (machinery and wire weaving)

- HAVER & BOECKER Niagara (mineral processing technology)

- IBAU Hamburg (silo technology)

- Sommer (mixing technology)

- Feige FILLING (filling technology)

- BEHN + BATES (packaging technology for food)

- AVENTUS (packaging technology for free-flowing bulk materials)

- NEWTEC BAG PALLETIZING (palletizing technology)

- W.S. TYLER (wire mesh and particle analysis)

- MAJOR WIRE INDUSTRIES (Flex-Mat® vibrating wire screens)

- NEXOPART (partical laboratory analysis)